Once all the metal studs where put in, I could put in the vertical parts to create a light cove. When this was done, I could put in the LED strips and connect the power supply and QuinLED. After a quick test run it was time to put in the ceiling plates.

With the help of Mo and Mattias we put in the 4 plates, which went pretty smooth. On to the plastering and painting.

Finishing tiling and starting ceiling

Time flies when you are having fun. But that does not finish the bathroom. So after putting in the last tiles a few weeks ago, it was time for the grouting, which again was a finishing touch.

Next up was the ceiling and the indirect light. I made a combination of the lowered ceiling and a place to connect the vertical part that will hold the LED strips.

In the mean time all stores are closed due to corona, but luckily ABC already had a web shop and they offered the option to pick up the order from the store.

A new desk and lots of tiles

With all this working from home I figured it was time to get a sit-stand desk. After some research I found the best value at Ikea. Since there still a good normal desk, I just ordered the mechanism. After a putting it together I put it under the desk and raised it. It turned out a great investment. I change between sitting and standing several times per day.

During the weekend it was tiles, glue and more tiles. Slowly a real bathroom emerged.

Tiling the bathroom

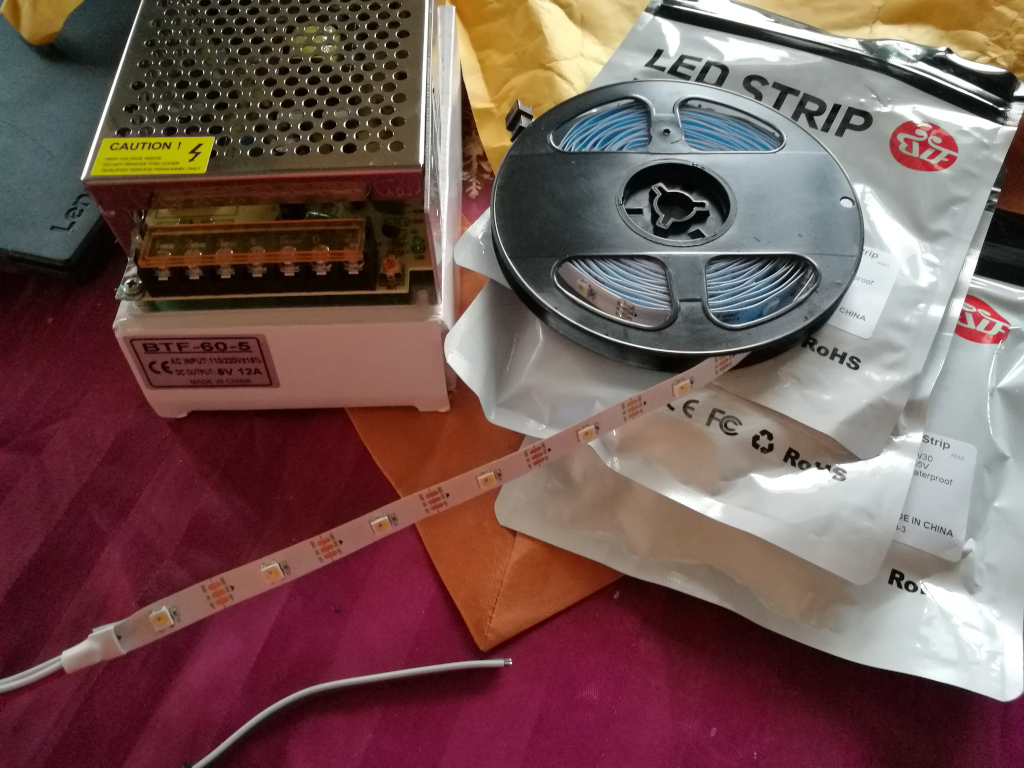

Sometimes there are weeks where a lot of visible things happen and then there are weeks like these. Little to report. Some parts for the livingroom lights came in quicker then expected. I had ordered a QuinLED controller as I had heard good things about it and also ordered a powersupply and RGBWW LED strips that besides colour also can emit warm white light. I tested the combination and then put them aside until I will get to the living room.

Beside I finally had some time to figure out what was wrong with the cable to the last LED strip in the bedroom. After some measuring I concluded the cable was broken. With a bit of effort I was able to use the old cable to pull a new cable behind the ceiling. Some more effort consisting of cutting, stripping, and soldering and the third LED strip also lid up.

And than it was weekend and finally I could start tiling the bathroom. The first part took a lot of time as I first had to work my way down to make sure the tiles would line up with the window. From there on al the other tiles will be aligned. But a great start!

The bathroom window

Time flies. After making the plans for the bathroom window, it took some time for Mo and me to get to the glass shop and double check on the colours of the stained glass and which frosted glass to pick. But then we could instantly order the glass and the lead strips that had to connect the pieces.

While waiting for the delivery, I sanded and painted the windows frame. Since it is Mondriaan design we picked black. It looks very classy.

A few days later I could pick up the glass and the I could finally put everything together. I started by laying out all the pieces and cutting the lead to size. Then part by part I put in the glass and put in the nails to hold the glass before I could put in the glazing putty.

The result was so nice I instantly wanted to make a picture to send to Mo, who was at work. I put the window in place and kind of had to push it in as it was a bit tight. Click , picture, click, another picture. OH NOOO. There the frame fell towards me and the a big bang a lot of glass broke. Tears forced their way out. I was so sad.

A bit later everything was cleaned up and I had ordered 4 new pieces. The positive side was that only white and blue had broken which where the cheapest colours. Luckily the replacement glass was available soon, and the result was just as great.

Earlier in the week I had lost my phone so some of the posts have a few pictures less then normal since I had not synced my phone for a while.

LED strips for the bedroom

With the new year, the winter also started. In the past weeks there was regular snow and wintery temperatures up or better down to -10.

Nice weather to work inside. Just over a year ago I already made a test setup, so I guess it as about time to actually put this stuff together. After some first trying it was not working stable, but with the help of some forums and my uncle I got the controller stable by adding a so called level shifter. Unfortunately the manual where somewhat unclear on how to connect them, but once I got it connected, the software was running stable and all effects instantly where picked up by the LED strip.

Time to cut the LED strips to length and install them on the beams in the bedroom. The first strip went pretty smooth and also the second strip was connected quick enough, but for some reason the third strip did not work. I need to really look into what is going wrong here some other time.

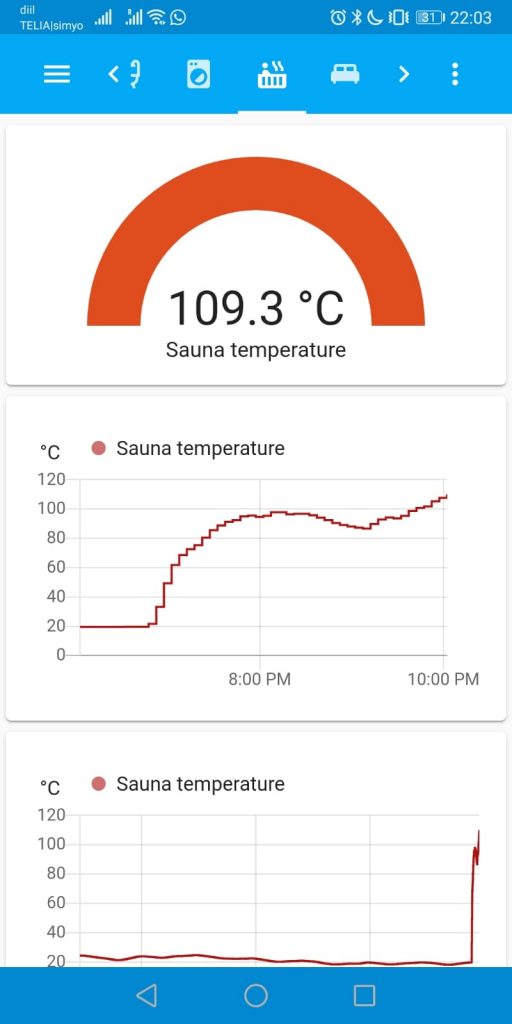

During the weekend we had a sauna, since the wooden floor parts are almost gone I changed to different wood, which seemed to burn hotter then the floor parts, with the result we had an unplanned new record high in the sauna. Good thing the garden is full of snow, so we could cool down making snow angels.

Start of a chair

About two months ago I talked with Mo about her birthday present. As I found out she is very fond of ‘De Stijl‘ I aked if she would like a Rietveld chair for her birthday, which would be delivered a bit later… Time flies so it was about time to start building it. As wikipedia has a full list of used parts it was pretty easy to calculate how much wood I would need. Since beech wood is very hard to get in Estonia, I used pine.

I started with a beam that I cut to length, then I cut them to size followed by drilling the holes for the dowels. When dry fitting them, it quickly started to look like the chair. As I did not have the sheet wood, I put a few other pieces to get a feel of the later result. Time to get paint.

With these darker days it was getting a bit annoying that the light in the garage kitchen did not work. After testing together with Jan who stopped by for a visit, I consulted with Loeke. The solution was actually pretty simple. It turned out the common ground and the switched ground where close to each other, and not explicitly marked. Since the switched ground strip was full I had continued with the common ground, which is a different circuit, so the circuit break did work as designed. I added a extra strip to split both grounds up and then I had light in the kitchen and under the train roof.

In the mean time it seems winter has started with a nice layer of snow and temperatures under 0.

The workshop

Secretly I had already started to use the work bench, which also stimulated to create a bit more order in the tools. I had seen a nice design of so called french cleat storage wall and wanted to try this. So I made a few small tool organizers. Because of the system you can easily move a set of tools do a different part of the workshop. After building this test setup I am convinced I will use this system to store the rest of my tools later on.

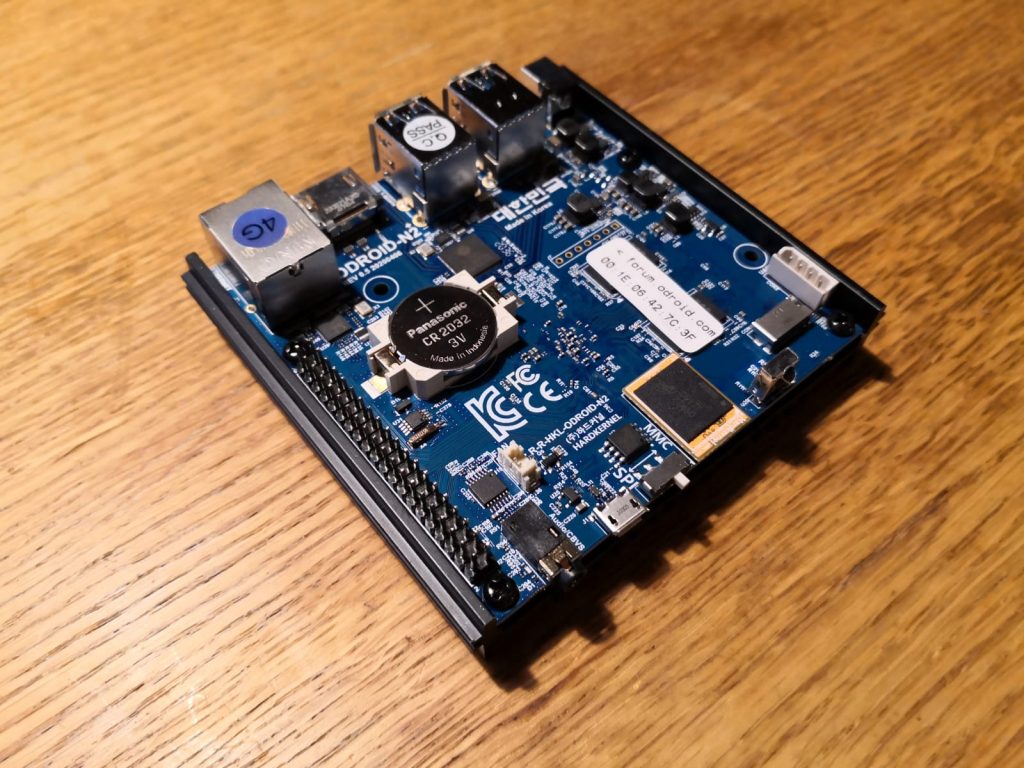

A few days later a new toy arrived, an Odroid N2+ with ‘gorgeous’ aluminum case, shortly the Home Assistant Blue, as an upgrade for my Raspberry Pi 3 to run home assistant for the upcoming years. So the darkest time of year I had something to keep me busy. Of course the first thing I did was open the case to check the content (and to turn it around to the connector where on a more logical side.)

Getting rid of the machine (2)

With the lessons learned from last week, the second part of moving the bigger part of the machine went smoother, but also because it was heavier, it still took an afternoon of playing outside.

As the scrap yard was closed already we went there the next day. With the 20 ton crane it was easy to lift the machine off the trailer. The main part was just over 350 kilo and the total was good for around 80 euro. Let’s not count hours, just enjoy the little extra towards the building budget.

With this big heavy thing out of the way I could finish the last part of the drive way. It really is another finishing touch.

Getting rid of the machine

With the house we also got some old machine that was standing in the garden in front of the garage. I was very heavy, so it had been standing there ever since. It seems it has been standing there for years, as I have seen glimpses on old Google maps images.

Together with Martijn we planned a day to lift it and move it onto the trailer, so we can bring it to the scrap yard.

Long story short, we had a lot of fun, it took ages, but in the end we got the first piece on the trailer just after sunset (which is around 15:20 this time of year, but still.) Next week the second piece.

Spelling error report

The following text will be sent to our editors: