Today was Wednesday again, so time to work on the house. I had a late start as we had a new co-worker coming in and something went wrong with his hardware, so I dealt with that before getting to the house.

I was clear the house had not been heated very long the past weekend, as it had cooled down to 1 degree. It had been like that for just over a day, so likely that is more or less the minimum temperature.

After starting to heat the place, I wondered what I should start on. As there now are so many things. Mo asked if the boys could help, so I asked them to check out the plan for the canalization and to find out details like size of the materials, depth and other things they could find out.

I decided to first move down the outside light so the camera has a free view. Of course this did not take very long, so the next thing would be to check out the materials for the new electrical system as once I have that in, I can always draw an extra line when I have some time left.

As I had to pick up some chainsaw oil from ABC, I checked out the prices and materials they had to offer before going to a specialist. At Esvika they carry the Harju Elekter line of enclosures I saw from several friends. They are pretty big and have an integrated place for the power meter. In real life it looked nice as well, so I decided to get one and get the components Henk had recommended. When you are from the Netherlands this kind of shopping is very nice, as the prices here are so much lower for this material.

Back home I fitted all components in the enclosure and then visited Martijn to check out how the wiring had been done at his place.

There I found out I had forgotten to get branch connectors as the 3 phases and the neutral need to be distributed to different components. I checked out the construction store, but I guess I will get back to Esvika later on to get some good stuff.

Month: January 2019

Insulation research

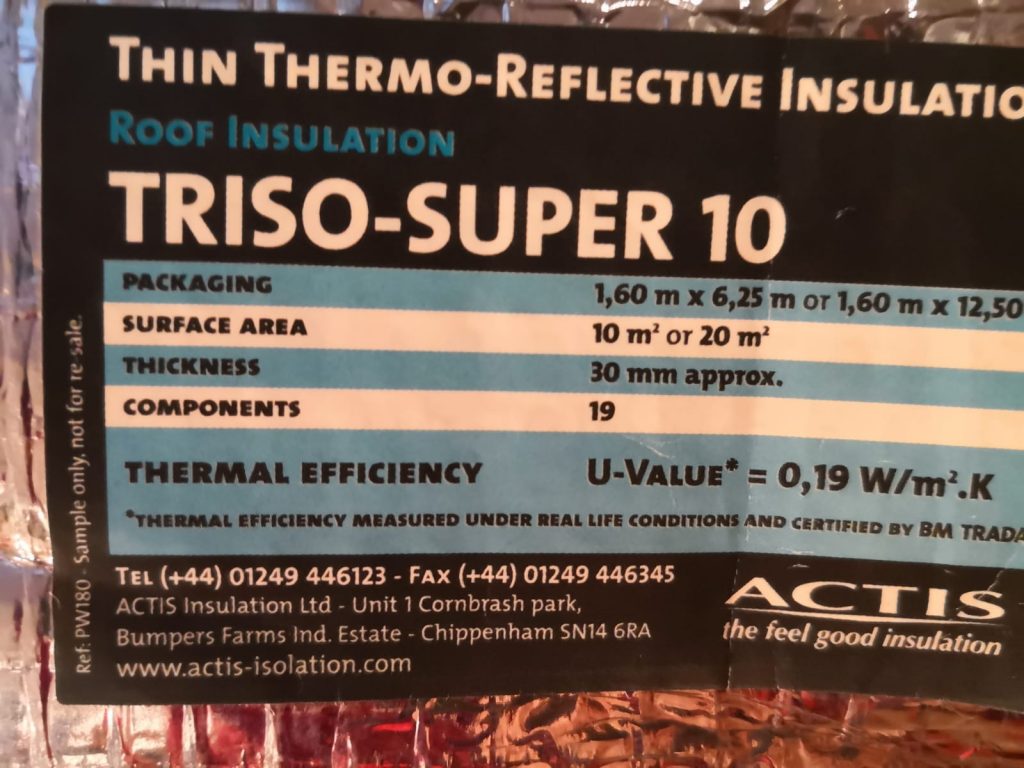

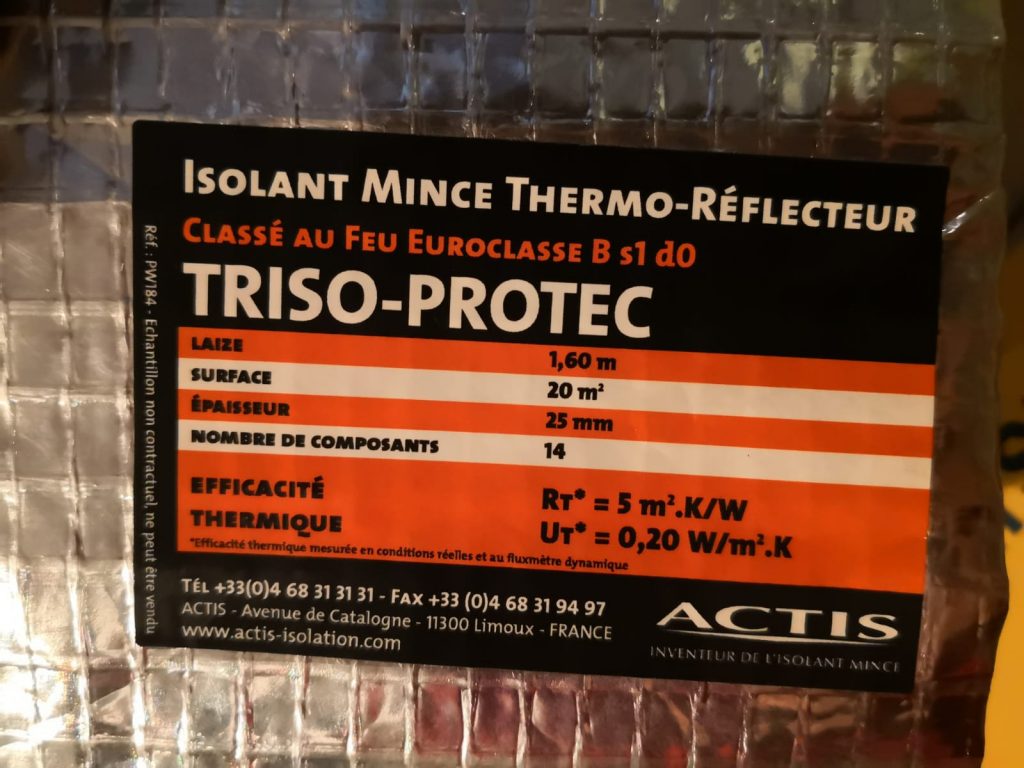

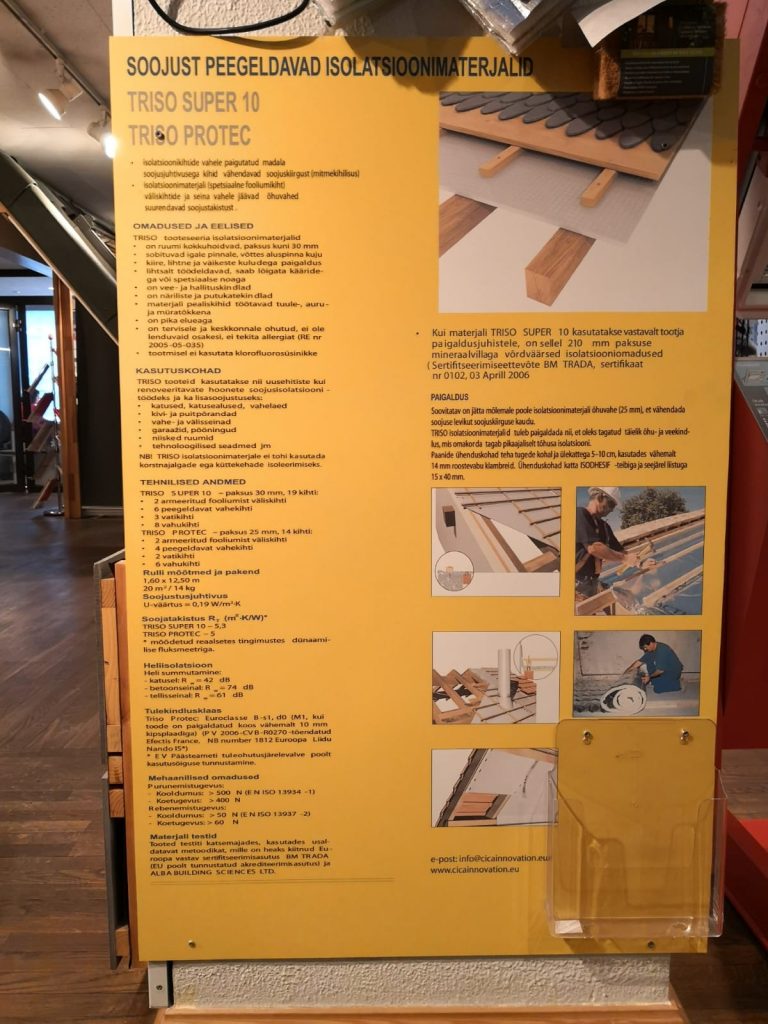

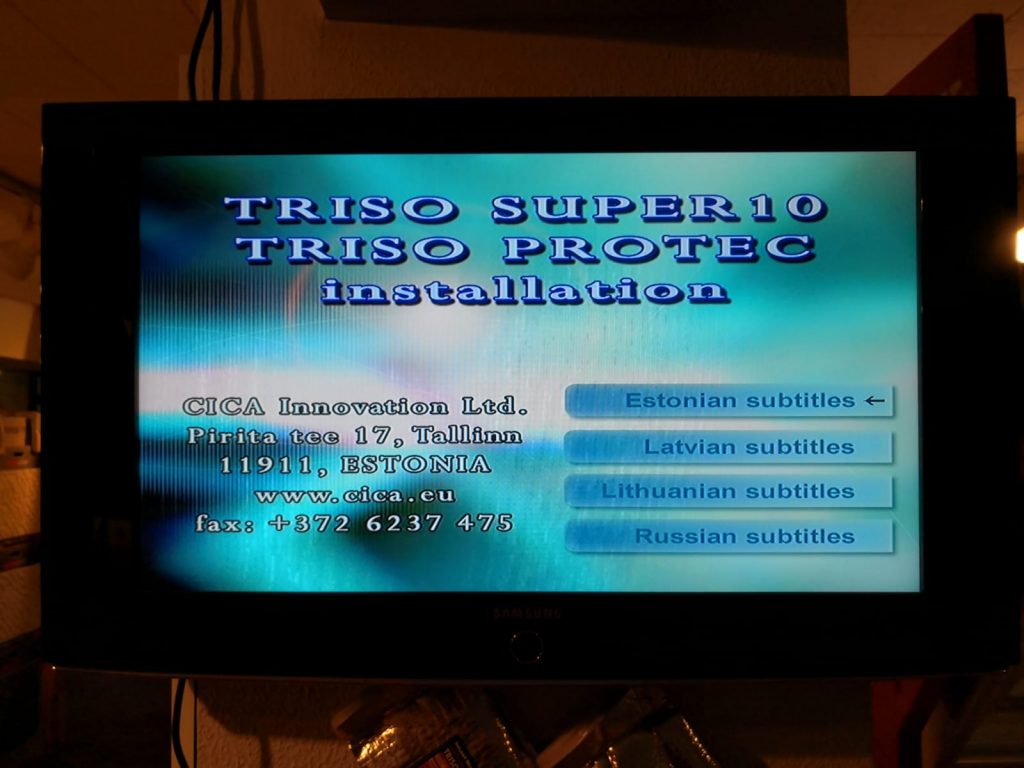

I think I have written before about he insulation material my dad found out about. It has 19 layers, is 30-35 mm thick and has the same insulation value (R-value) as 20 cm of glass wool! Since this will safe a significant amount of space, I was very interested to find out if I could find this material in Estonia and if so, if I can find use-cases and experiences.

Today before work I stopped by a some construction advice center I had found out about a few months ago when I was visiting a co-working space.

After entering I made a circle toward the right of the place, when I was almost fully around, I found the material. I made some pictures of the information as they where out of flyers, so I could look up the rest of the information online.

Unfortunately I found out later on that the local websites mentioned where not active anymore, but at least I have a brand name to work with. To be continued.

Creating a drawing

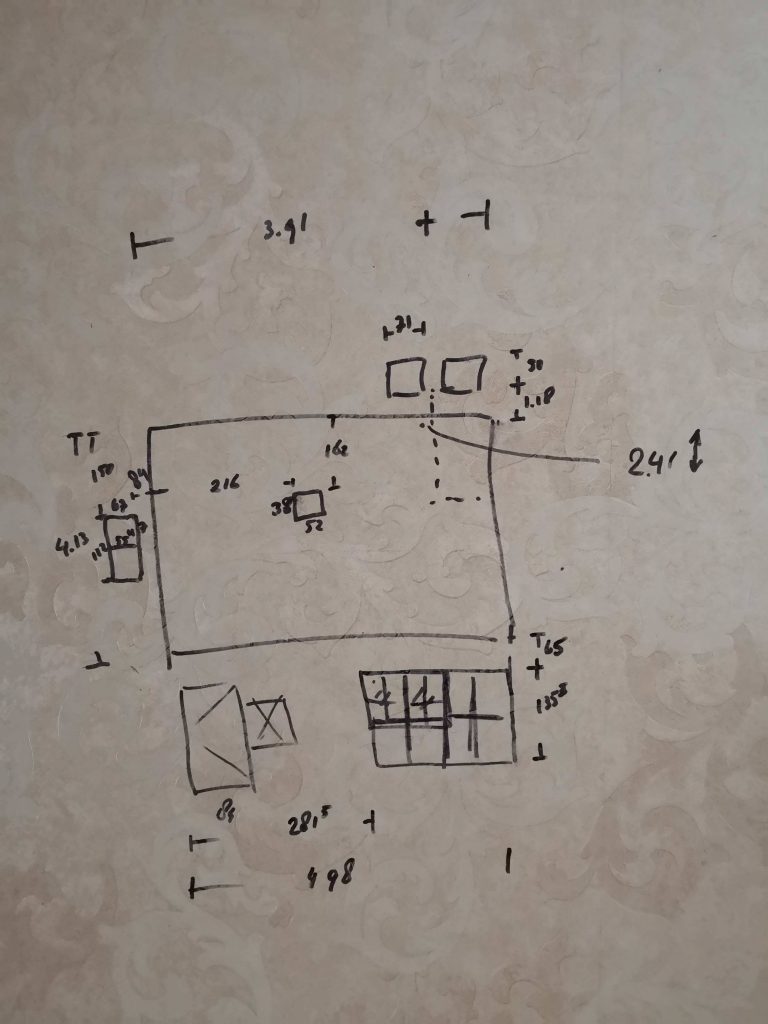

With all the measurements of last weekend, I made a drawing in floorplanner. I have a feeling they dumbed down the free version a bit, but it still is a nice tool to easily draw a 2D and 3D version of your house.

I added two exports. In the 3D version you see the rough sketch I made earlier on the base of the paper floor plan still in the background. At some point I will likely delete that part. The measurements in the 2D version are for both constructions, so they are a bit off.

Measuring brings knowledge

This was a weekend of little work as my dad and sister where visiting. They where impressed by the work done so far and really like to see the place in real live, so now the picture make more sense as well.

On Sunday my dad and I went to the house to heat it up a bit and take measurements. Especially for the planning of the bathroom/sauna part and the kitchen exact measurements are important. Besides we took down the last beams of the wall near the heater.

About ready to build

This afternoon I finished the last part of the room, cleaned the ceiling from spiderwebs, took out the carpet and than all of a sudden, this part of the house was about ready for some construction work. My dad and sister will be visiting this weekend, so I don’t expect very much work will be done, but after that at least the house will be ready.

While I was cleaning the ceiling I checked part of the ceiling above the stove to see how heavy the beam was that was used over the former wall. I was happy to see it was over 20 cm, so there should not be any problem taking the beams that have been used for the wall from underneath. The ceiling surely will not come down.

A dusty afternoon

As I wrote two days ago already. The last meters go slow. Today was another day of ungrateful work. You see little progress, but the work needs to be finished before I can start building.

In the morning i started cutting some of the wood into piece that would fit into the stove, so I can heat the place easy. After that I took out some last pieces of the ceiling in the former kitchen and around the stove and vacuum away the spiderwebs. When I was done, I could clean up the saw dust that I found a lot above the ceiling and organize the wood next to the chimney.

Around lunch I took some time to do something fun. I installed MQTT on my Home Assistant and set up two automations for one of my Sonoff switches, so the outdoor light would turn on 10 minutes after sunset en turn off at 22:30. (I just need to rearrange the light, but for that I need a ladder.)

Then I started the work intensive job of taking down part of the old plaster work with metal mesh from one of the walls. I must say I am glad this is only found in one room. It is very time consuming and dusty work. But with small steps you get to your destination also.

I moved the trash to private trash sorting station and then was done for the day.

The last meters go slow

Another day of finishing off. Plus I wanted to connect the outdoor lamp and install a motion sensor to turn it on. And since the security camera should go at about the same place. I would install that as well.

To prepare for the installation I took out the last pieces of ceiling and some of the wall covering consisting of a layer of hard and some plaster plate. before you got to the wooden wall covered by some black cardboard I had found before.

The actual installation of the light took more time then I liked. It was -6, but the wind made it feel as -15, so it was not the most pleasant time to be outside and working with gloves on sure has it’s effect on the fine movements. For the camera I needed to drill a hole. I picked a spot near the original hole of the power cable only to find out the drill was not long enough. So I drilled inwards from the outside. I still could not see through. When I poked with a long metal rod I found out that exactly in the middle of the wall where the drill met there was another layer of the black cardboard. I punched through and then I could take the wires through the wall. The wall was about double the thickness I expected. This makes my preference for the thin insulation foil even stronger. Let’s see if I can find out about the availability in Estonia this week.

Once the light and the camera where working I found out the camera picked up a bit to much of the light, which blocked the view to the gate, so later on I have to lower the light a bit.

Time flew and after taking down some more left over pieces of ceiling it was time to go home already. No need to ask what I have to do later this week.

Finishing off

After I took Friday off, this weekend, I planned to finish the demolition and clean up, so the house is ready for insulation, new electricity, canalization and more.

I started in the smaller part of the house, which will be the future bathroom, sauna and washing room. When I was done demolishing the last stuff, I decided to check if the door in the back would open with one of the keys that I had found. One of the keys fit and after I removed a screw from the outside the door opened pretty easy. This saved a lot of time to get everything out. Since we do not have a new container yet, I decided to collect it on separate piles under the roof behind the garage.

When I took of some ceiling covering and insulation I found a rotten part in the ceiling that came out very easy. (It was situated under the access hedge for the small chimney.) At the final cleanup I also found some floor boards which had seen better times. These are the first bad parts in find in the house, and they are relative easy to replace, so I am pretty happy.

When I wanted to move the wood to the wood storage I was not happy with the way it was stacked. Because of all the nails, it was pretty messy, so I decided to invest some time and take out the nails.

This took longer then expected, but in the end all the wood including a few dozen planks I added took less space then all the wood before. This organizing can be very satisfying.

Estonian get rich quick scheme

Today the container was finally picked up and we were confronted with some ridiculous charges. As I wrote before, according to the rental company you can fill a 10 m3 container with 1.8 tons of mixed construction waste. Just for reference, 1 m3 of bricks weighs around 1.6 ton and 1 m3 meter of wood weighs around 500 – 550 kg. So in 1 to 4 m3 of construction materials you would reach the limit while your container isn’t even half full.

Our container weighed 6890 kg minus the weight of the container (1200 kg), minus the 1.8 tons of included weight. So we where 3890 kg overweight with the container about 2/3rd full. The company charged us more then the container price in overweight charger. When I asked what kind of material they expect to will a 10 m3 container with to reach only 1.8 tons, they did not have a real answer. I also asked where I could send the bill for their no show on Monday. That they also did not know. To be continued, but it seems this company underestimates the power of word of mouth advertisement. This is at least the last business they do with us.

A fruitful day

Today I took the day off, as a matter of fact the next 4 weeks I will have the day off on Wednesday to work on the house. I had planned some investigations so from my findings I could adjust my plans.

One of the first things I planned to do was open the hatch and check out the cellar. It was smaller then I thought, about 60 cm deep and 2 by 2 meters more or less square. This will make any sewer plans more complicated.

Then I checked the living room for hatches but there where not any. So I checked out the hole in the floor near the water meter. It turned out all the floor board where laying there without being nailed down. So I took one out and discovered the floor was insulated.

I took out some more and found out the section of the floor near the water meter had a big nest of mouses ore even rats. I cleaned that away and will need to replace this insulation later on.

I opened the second layer of floor board under the insulation and found out here there was about 20 cm of space. To make sure this was all over the place I opened the floor boards in the corner, the place where we now are planning to bring the sewer into the house.

To check how hard it would be to bring the sewer into the house I also made a hole on the outside of the house in the corner. The good thing was that the ground was pretty easy to dig in. Up to half a meter it was black dirt.

After lunch I added some light to the hallway, to the corridor near the front door and to the former kitchen. That way we have to work less with extension cords passing doorways. I guess the rest will come after I can the new fuse cabinet.

The last thing for today was taking out the last part of the ceiling. Now, apart from some details the entire ceiling is free. I found 3 place where it has been leaking, so at some point I need to fix those leaks before I will put in a new ceiling.

Just after 21:30 I finally got home, where Mo had cooked another wonderful meal. It is wonderful to have her support me this way!

P.S. The container has still not been picket up …

Spelling error report

The following text will be sent to our editors: